-40%

Lauda TD2 Automatic Tensiometer System W Eco RE425 Chiller, Controller & Printer

$ 3590.4

- Description

- Size Guide

Description

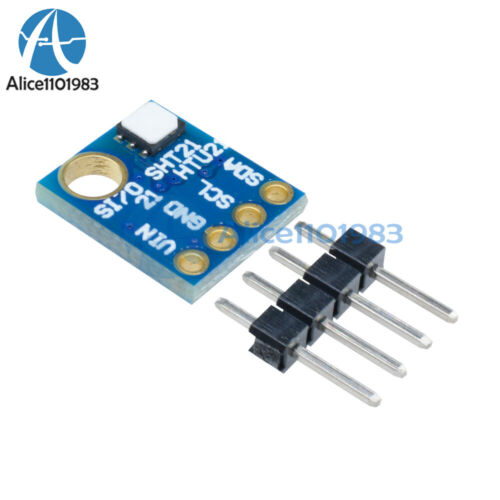

Lauda TD2 Automatic Tensiometer System consisting of(1) LAUDA automatic Tensiometer type TD2W

(1) LAUDA Eco RE425 recirculating system model: eco RE 415 with Eco Gold recirculating heater.

(1)LAUDA C Command Control pendant

(1) Custom Printer model PCDP40-

What you see on the pictures is what you’ll get please see pictures.

The right temperature worldwide

Technical data

Measuring stand

Surface and interfacial tension; density, weight

Measurements surface and interfacial tension

mN/m

➢ Resolution

Temperature range

Temperature measurement

➢ Resolution

➢ Accuracy

Density measurement

➢ Resolution

Weight measurement

➢ Resolution

Calibration

Display

Measuring mode selection

Parameter input

Sample designation

Measuring point interval

Data storage

Stage movement

➢ Stroke speed

➢ max. stroke

Maximum detection

Ring correction

Magnetic stirrer

Stability criterion

Interface

Documentation

Data transfer Software

Weight

Power Consumption

Dimensions (measuring stand) (WxDxH) Power supply

mN/m

0.01

Standard accessories

Recommended accesories

Measuring technology standards

✜ Two-legged ring Circumference:

✜ Calibration weight (plate/frame): 100 mg

✜ DIN 53914 ✜ DIN 53993 ✜ ASTM D971 ✜ ISO 304

60± 0.2mm,Ø0.37mm

✜ Calibration weight (ring): 500 mg ✜ Plunger: 0.5 cm3

✜ Tweezers

✜ Spare thread with hook

✜ Set of 10 sample beakers Ø 5 cm

✜ Wilhelmy platinum plate:

✜ Double walled glass tempering vessel (inc. cover) Ø 5 cm

WxDxH: 19.6 x 0.05 x 10 mm ✜ Glass immersion plunger

Surface and interfacial tension in study and education at the touch of a button.

LAUDA Tensiometer TD 2

density fixing

WINDOWS (optional)

° C

5 - 85

° C

0.1

° C

+/- 0.5

kg/m3

< 2000

kg/m3

+/- 1

mg

< 5000

mg

+/- 0.1

Minutes

1 - 120, selectable

Results mm/s

Max. 500, with date and time

mm

80

kg

Approx. 4.0

kW

0.01

mm

250 x 120 x 250

✜ Set of 10 sample beakers Ø 8 cm

✜ Spare silk thread, approx. 1 m

✜ Tempering stage with magnetic stirrer

✜ ISO 4311

✜ ASTM D1331 ✜ ASTM D1590 ✜ ISO 6295

✜ ISO/DIS 1409.2

(optional)

✜ Digital temperature sensor for

Thermostats · Circulation chillers · Heating and Cooling systems · Interfacial instrumention & Viscometry instrumention

Product information

LAUDA DR. R. WOBSER GMBH & CO. KG · P.O. Box 1251 · 97912 Lauda-Königshofen · Germany Phone.: +49 9343 503-0 · Fax: +49 9343 503-222 · E-mail: [email protected] · Internet: www.lauda.de

Digital (optional)

Calibration weight (Ring: 500 mg / plate: 100 mg)

Graphic display 320 x 240, 11 x 40 characters

Menu-controlled (Ring / plate / density / weight)

Menu-controlled

Numerical

DC motor

Selectable in 10 steps from 0.1 - 1

Scanning from 10 to 100 %, automatic

Automatic according to Zuidema und Waters

Control integrated; table with stirrer optional

Standard deviation by user-defined 3-9 measurements

RS 232

Printer, PC (optional)

For PC based on WINDOWS 98 SE and higher (optional)

External power adapter, 90- 264 V; battery adapter (optional)

Tensiometer TD 2

Applications & Advantages TD 2

The LAUDA Tensiometer TD 2 is used to measure surface and interfacial tension, to determine the density of liquids and to measure small weights. The fully-automatic and cost-effective

instrument consists of a precise electromagnetic weighing cell plus a remote control panel with a userfriendly graphic LCD- screen for precise measurements.

Fully automatic yet simple and precise

New Measuring Options

The successor to the TD 2 accomplishes the move to fully auto- mated tensiometry and maximises user convenience directly over a PC. This extremely compact stand-alone device offers everything needed to measure surface and interfacial tension at the push of a button either in the laboratory or in the field as simply as possible. The accurate, reproducible results can be displayed, printed, saved, or transferred to a PC. With this devi- ce it is also possible to measure the density of liquids and to de- termine small weights. The convenient external control panel has a large graphic display that can be operated intuitively with- out special training. The integrated microprocessor handles sample positioning, force maximum detection, and data correc-

tion. The program repeats measurements until a user-defined stability is reached and calculates static surface/interface tensi- on and standard deviation over the last series of individual mea- surements, and compiles the results in easy-to-understand ta- bular format.

➢ High resolution (± 0.01 mN/m, ± 0.1 mg) and expanded measuring range up to 300 mN/m up to 5 g

➢ Automatic maximum detection and maximum scanning with selectable range

➢ Tabular representation of individual measurements, number of measuring points, measuring time, corrected and

Advantages TD 2

The LAUDA Tensiometer TD 2 is easy-to-operate and supplies surface and interfacial tension of liquids at the touch of a button. It is therefore particularly suitable for beginners and for education. Surface and interfacial tension values are displayed digitally. The selection of measuring methods is simple and calibration is implemented using standard weights.

Control panel Command

Application options

There are numerous applications for the LAUDA Tensiometer TD 2. It is used for example to determine and test physical properties of solutions, organic and inorganic liquids, liquid/liquid or liquid/solid dispersions, emulsions, etc. or to develop and test surface ac- tive substances such as surfactants and emulsifiers and to identify the such substances in effluents and in waters.

Measuring stand

Example: Control of cleaning water

The measuring stand is equipped with a high-resolution load cell and a DC motor for smooth movement of the measuring table with 10 sel- ectable speeds. A temperature sensor and magnetic stirrer can be connected to the device on request. The accessible sample chamber allows the use of standard sample beakers up to 8 cm in diameter.

Surfactant traces left from cleaning agents can negatively affect foam formation, e.g. in beers, and must be prevented. A surfactant analysis would take too much time and would be too expensive.

Solution: It can be determined whether traces of surfactant are present in the rinsing water by measuring the surface tension with the TD 2, e.g. using the ring method, and then comparing it with that of pure water.

With its rugged design, ease of operation, and high precision, the TD 2 is ideal for use in all quality control applications. Since measurements are taken completely independently by the user and documented together with the required settings, the device also meets the stringent requirements of the GLP guidelines.

uncorrected data (surface/interfacial tension, density)

➢ Automatic ring correction (based on Zuidema and Waters)

➢ Automatic control of data stability based on predefined standard deviation

➢ Semiautomatic calibration in three accuracies with standard weights

➢ Input of ring/plate geometry possible

➢ User-defined measuring point density and measuring time

➢ Storage of up to 500 measurements with related parameters

➢ Numerical user-defined sample designation

➢ Direct or subsequent output of data to optional printer or PC (optional data transfer program required) via RS 232 interface ➢ Measurement and documentation of temperature in the sample by means of digital temperature sensor (optional)

➢ Magnetic stirrer control for homogenisation of disperse samples

23

Basic components:

This convenient control panel allows the complete remote operation of the measuring stand (movement of sample table, input of measuring parameters, start of measurement, and transfer of data over RS 232 interface to printer or PC). This minimises vibrati- ons to the measuring stand. The high-resolution graphic display offers menu-based user guidance and displays individual measu- rements and results in tabular format.